The Limitations of Traditional Quality Control Methods

Quality control is a crucial process that ensures the products and services we enjoy meet the highest standards. Think of it as the ultimate detective work for products. Traditional quality control methods, however, are increasingly inadequate in today’s fast-paced world, relying heavily on human inspectors who meticulously examine each item for flaws. This approach is often slow, tedious, and susceptible to human error. In an era where consumers expect perfection, it’s clear that change is needed.

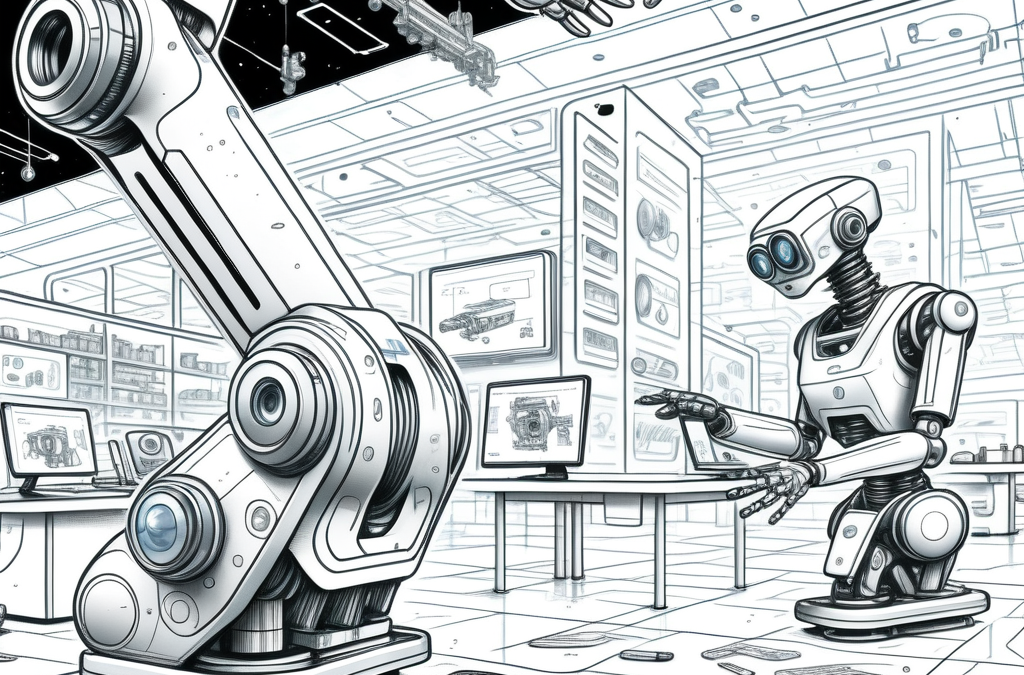

The Power of AI in Quality Control: A Game-Changer for Industries

Enter artificial intelligence (AI), a transformative force ready to revolutionize quality control processes. AI technologies bring a new level of precision and speed that was previously unimaginable. Here’s how AI enhances quality control:

- Computer Vision: AI systems utilize advanced algorithms to detect defects in products that might be overlooked by the human eye, scanning thousands of items in just minutes.

- Machine Learning: These systems continuously learn from data, improving their accuracy over time and ensuring consistent quality.

- Anomaly Detection: AI can recognize what’s normal and flag anything unusual, catching potential problems before they become major issues.

The applications of AI extend to various industries, including:

- Automotive: AI-powered cameras inspect every detail of a car’s paint job, identifying even the smallest flaws.

- Food Processing: AI assesses the quality of fruits and vegetables, sorting them based on freshness and ripeness.

- Healthcare: AI enhances the quality of medical imaging, ensuring accurate diagnoses.

Implementing AI in Quality Control: A Step-by-Step Guide

Implementing AI in quality control is akin to leveling up your favorite video game character. It boosts your capabilities and enhances overall performance. Here’s how to effectively integrate AI into your quality control systems:

- Assess Your Current Setup: Evaluate what’s functioning well and where the bottlenecks are. Identify areas where errors frequently occur.

- Choose the Right AI Solutions: Align the AI technology with your specific quality control needs, whether that’s computer vision systems or predictive maintenance algorithms.

- Overcome Technical Barriers: Be prepared for potential infrastructure upgrades, as many AI systems require robust hardware to operate effectively.

- Train Your Team: Provide thorough training on AI tools, emphasizing collaboration rather than competition. AI is there to assist, not replace.

- Start Small and Expand: Implement AI in manageable phases and learn from initial experiences before scaling up.

AI Quality Control Techniques for Beginners

Diving into AI quality control may seem intimidating, but it can be incredibly rewarding. Here are some beginner-friendly techniques:

- Machine Learning: Train computers to learn from experience and identify defects by providing ample data sets.

- Image Recognition: This allows AI to quickly assess products, such as checking for burnt cookies on a conveyor belt.

- Anomaly Detection: Just like noticing a friend wearing a different outfit, AI flags anything unusual in product quality.

To get started, consider learning basic coding languages like Python, commonly used in AI projects. Online courses and tutorials can introduce you to machine learning and its applications in quality control.

Remember, data quality is paramount. The more high-quality examples you provide for the AI to learn from, the better its performance will be.

Real-World Applications of AI in Quality Control: Success Stories

Let’s take a look at companies that have harnessed AI to transform their quality control processes:

- Tesla: With an AI-powered computer vision system, Tesla has dramatically improved its quality control efficiency, reducing defects by an impressive margin.

- Procter & Gamble (P&G): By analyzing customer feedback using AI, P&G quickly identifies and resolves product quality issues.

- Coca-Cola: Their AI monitors vital factors to ensure every bottle maintains the iconic taste that customers expect.

- Samsung: AI enhances smartphone camera quality by analyzing millions of photos and optimizing camera settings.

- GE Healthcare: AI ensures the quality of MRI images, enabling accurate diagnostics for better patient care.

These examples illustrate that AI isn’t just a buzzword; it’s making a tangible impact in quality control across multiple industries.

The Future of Quality Control: Trends, Challenges, and Opportunities

The future of quality control is bright, with AI paving the way for incredible advancements. Some exciting prospects include:

- Autonomous AI Systems: AI could evolve to refine its own quality control algorithms without human input.

- Integration with Blockchain: This could create secure records of quality assurance processes.

- Advanced Predictive Analytics: AI will predict quality issues before they arise, enhancing proactive measures.

However, it’s essential to ensure transparency in AI decision-making and avoid over-dependence on automated systems. The balance between human oversight and AI efficiency is crucial for sustainable progress.

Conclusion: Embracing the AI Revolution in Quality Control

AI is not just transforming quality control; it’s setting new standards for excellence. From enhanced accuracy to significant cost savings, the benefits are clear.

So, what’s next? Explore the world of AI-powered quality control and discover how you can implement these technologies in your projects or workplace. The future of quality control is unfolding, and it’s up to you to be a part of it. As AI continues to evolve, what new possibilities will emerge for quality control? The adventure has just begun.